Square Nippers

VESSEL provides a generous selection of blades for all wire cutting needs, including resin products gate cut and automatic welding equipment.

- The position of air intake port is 180-degree rotatable.

- Two air intake ports are provided, so they can be switched depending on the mounting place.

Open E-Catalog

Watch Video

Round Nippers

- The position of air intake port is 180-degree rotatable.

- Two air intake ports are provided, so they can be switched depending on the mounting place.

- These are fixing hardware for sprue cutting of direct gates or mounting to an automatic machine.

- This unit is to be used in case the originally required pressure is not obtainable by the limit of space and air pressure.

- The main unit is variable: the angle can be easily adjusted 0 to 600

Open E-Catalog

Watch Video

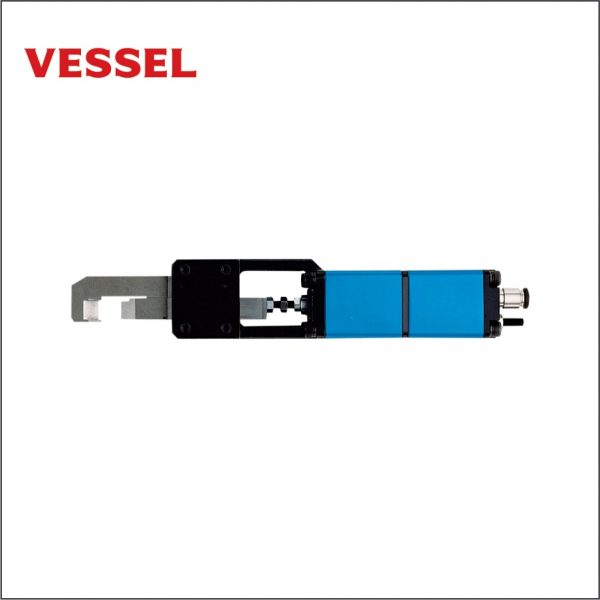

Sliding Nippers

Sliding Air Nippers Horizontal- Type

AIR NIPPERS

- Vessel’s patented. V-groove slide base ensures constant stable positioning. The unit is not subject to inclined loads and has achieved high precision gate cutting performance.

- The springless slide construction and a main unit ensures smooth movement and a V groove slide base has been employed for high precision positioning.

- These compact. lightweight nippers have been designed for easy mounting inside equipment and to enable secure mounting under high ensity mounting conditions.

- Blade gape is adjustable, and fine adjustments are to make after mounting the nippers, ensuring clean, unblemished cut surfaces.

Open E-Catalog

Watch Video

Thrust-Cut Nipper

Thrust Cut Air Nipper

- These nippers are equipped with a foot switch and are linked to high precision drivers enabling the cutting of film shaped gates from the thin end, preventing wrinkles around the cut.

- This is a dedicated set of blades for GT-NK 10. Suitable for processing of film gates attached to robot hands.

- Connected between the compressor and the air nippers.

- The timing controller enables adjustments to the slide and cutting timing (Approximately 0.5 seconds to 1.5 Seconds).